home / equipment / shirt finishing double buck

Double Buck Shirt Presses

Rotary w/Sleeve Press

Cabinet Flat Heads w/o Sleeve Press

Cabinet Contoured Heads w/o Sleeve Press

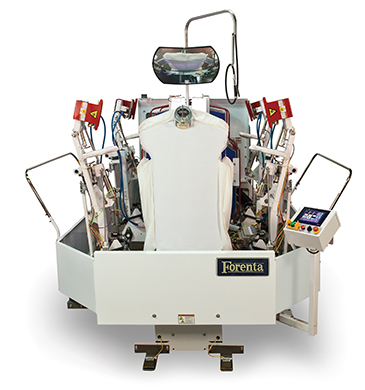

851RDSP Rotary Double Buck

New high-volume blower, duct, air heater and steam injection for sleeves for faster finishing

Foot=switch control of collar clamp, vacuum and cuff clamps for operator ease

Two-position sleeve arm height adjustment with automatic angle orientation to accommodate all types of shirts

Porous air-bags for drying the yoke and sides of the shirt

Water spray and mirror standard

Reduced floor space needed

Color touch screen

video demo

802DBV Double Buck Cabinet Shirt Press

Flat Heads

Special Head and Buck Design for Quality Finishing

Buck Designed with Yoke and Side-Drying Air Bags

Collar Clamp Automatically Opens for Operator Convenience

Shirts are Dressed on Front Buck and Rear Buck from Same Rest Position

Bucks Transfer Simultaneously for Faster Production

Bucks are Designed to Finish from the Smallest to the Largest Size Shirts

Water Spray Standard

620DBV Double Buck Cabinet Press

Contoured Heads

Shirts are Dressed on Front Buck and Rear Buck from Same Rest Position

Heated Bucks, Faster Drying, Eliminates Chemical Build-up

Heads and Bucks are Taller to Finish Larger Shirt Sizes

Bucks Transfer Simultaneously for Faster Production

Innovative Pre-Inflation Side Air Bags

Finishes Size 14 1/2 to 20

Vacuum Hold Down

Water Spray Standard

T: (423) 586-5370

F: (423) 586-3470

185 Cold Creek Drive

Morristown, TN 37814 USA

© 2018 Forenta, LP